Workplace Fatigue in Manufacturing: Best Practices for Minimizing Risk

According to the National Safety Council, fatigue costs U.S. employers more than $130 billion — that’s billion — a year in health-related lost productivity. A typical U.S. company with 1,000 employees can expect to lose more than $1 million each year to fatigue, which can often increase the workloads of other human operators. These challenges can be especially acute during global crises like the COVID-19 pandemic — as well as seasonal ramp-ups like the winter holidays.

Indeed, for many manufacturing organizations, the pandemic has shifted demand into overdrive, which means they’ve expanded very quickly — but without critical strategies in place to manage that growth efficiently. One of the unintended consequences? Employees pulling plenty of overtime and putting in many extended shifts. On the other end of the spectrum, some manufacturing organizations are facing a different scenario: budget constraints that have forced layoffs, which can mean fewer employees doing more work.

The result, however, is the same: tired, fatigued employees — which can lead to higher burnout, turnover, accidents, errors, and other incidents that present significant risk to your organization.

As experts in the growing field of fatigue science explain, fatigue risk management requires a far more targeted, strategic approach than the manufacturing industry has historically employed. According to Mike Harnett, a human factors specialist and president of Solaris Fatigue Management, the traditional culture of the industry is one major underlying factor. “Many people in top leadership positions got there by being sleep deprived,” Harnett explains. “Being tired, working long shifts, is seen as a badge of honor.”

But culture is just one challenge that workforce managers face in tackling this pervasive workforce issue. Harnett shared with Shiftboard additional insights that manufacturing companies should consider to develop effective fatigue risk management strategies within their organizations.

Recognize That Being Awake Isn’t Enough to Mitigate Workplace Fatigue

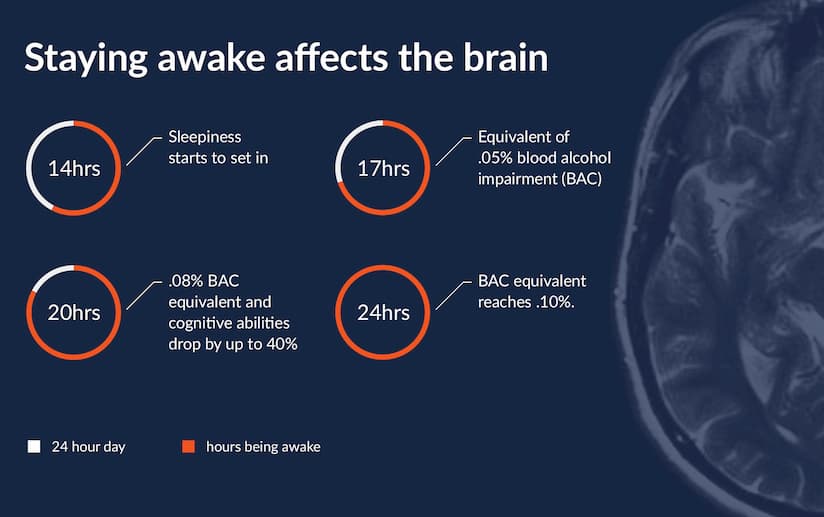

Simply put, the longer you’ve been awake, the harder it is to stay awake. Sleep pressure accumulates in the brain due to a depressant called adenosine. According to Harnett, after being awake for 14 hours, sleepiness starts to set in. At 17 hours, humans have the equivalent of .05% blood alcohol impairment (BAC); at 20 hours, that number jumps to .08% BAC, and cognitive abilities drop by up to 40%. At 24 hours, BAC reaches .10%.

In countries like the United States and Canada, it’s illegal to drive a vehicle at levels of .05% BAC and higher (the U.S. limit is 0.08%). Yet, it’s not uncommon in industries like manufacturing that employees are working long shifts with similar fatigue-driven BAC levels. Indeed, Harnett says that a startlingly high number of organizations have no established policies or guidelines about how to identify an employee who may be fatigued or what to do in those scenarios — which can be a stark, but necessary, starting point for getting the conversation started.

Prioritize the Design of Good Work Schedules

“The science is clear,” Harnett says. “Workplaces need to understand their role in the promotion and mitigation of fatigue. And the most important factor in their control comes down to the design of work schedules.”

With respect to their scheduling practices and policies, these are just a few of the factors that Harnett recommends workforce managers consider:

- Do we have extended-hour shifts that exceed 12 hours?

- Are more than three consecutive 12-hour night shifts worked?

- Is there less than 12 hours undisturbed rest after a 12-hour night shift?

- Do employees work more than 60 hours in a seven-day period?

- Are there irregular and unplanned schedules as a result of call outs?

- Are we monitoring our overtime and who is getting it?

Increasingly, technology can play a very effective role in answering those questions, providing invaluable insight into specific workplace fatigue risks. Workforce scheduling solutions like Shiftboard not only help manufacturers transform scheduling data into meaningful insights to shape effective fatigue management policies but also accurately enforce those policies, ensuring worker safety and productivity in the long run.

Identify Where Your Fatigue-Related Risks Are

Workplace fatigue is often underreported, especially in industries like manufacturing, where night shifts and extended hours are the norm for many organizations. It’s also hard to detect — especially if management isn’t accustomed to looking for it.

Fatigue experts note that an employee’s commute home can often be the most dangerous part of the shift. In addition, shift handovers can be problematic: Employees are often tired after their shifts, and transfer of critical information can be lost or compromised as they transition on or off schedule. Another common challenge? Not enough time off between shifts to allow for sleeping, commuting, and other basic life functions.

“It doesn’t matter what an individual does at home if their work causes excessive amounts of fatigue, or if their work schedule doesn’t accommodate for adequate recuperative sleep before returning to duties the next day,” Harnett says.

Take a Close Look at Your Company Culture Around Workplace Fatigue

In many manufacturing and front-line industries, a “tough it out” mentality often pervades the workplace culture, which stems from decades-old, top-down belief systems that success and long, hard hours go hand in hand. That can create a work environment where accepting (or ignoring) workplace fatigue can lead to major problems.

Harnett notes that such philosophies are starting to shift, especially as wellness continues to become a more mainstream topic instead of just a trend. In addition, millennial-age workers tend to place a higher value on work-life balance than previous generations. Even so, those deeply ingrained beliefs that normalize working long hours can be difficult to overcome — and recognizing the workplace cultures that perpetuate them is a critical part of developing healthy new approaches.

Consider Workplace Fatigue as Part of Your Employee Assessment Strategies

It’s considered standard for many manufacturing organizations to have regular drug and alcohol testing for employees. Fatigue assessment, however, doesn’t seem to make the cut.

But experts like Harnett strongly emphasize that it should. According to research, sleep disorders like obstructive sleep apnea, are highly under-recognized. About one in five Americans has obstructive sleep apnea, and — perhaps even more alarmingly — more than 75 percent of severe cases of OSA remain undiagnosed. That’s a lot of employees working while fatigued.

Consequently, assessing whether employees have such conditions — and how your workplace conditions may affect or exacerbate them — should be top-of-mind for workforce managers when creating strategies to mitigate workplace fatigue.

Go Beyond Coffee Breaks for Effective Fatigue Risk Management

Successful manufacturing organizations are those that implement proactive, creative strategies to mitigate fatigue risk.

Consider one of Harnett’s clients, which decided to renovate an on-site trailer into two distinct spaces for employee use: one for exercise, with some basic workout equipment, and the other for sleeping, with comfy loungers perfect for a post-shift snooze. (In fact, that’s what prompted the idea in the first place: one particular employee’s long commute following his shift. A restorative nap afterward helps lower the risk of a dangerous drive home — a win-win for everyone.) In this way, employees have two options to mitigate fatigue risk: by boosting their alertness levels with exercise or resetting with a nap.

But this example illustrates just part of the equation. Organizations also need to think about how they can support healthy, well-rested employees when they’re off the clock, too. Other creative solutions include employee assistance programs that cover the costs of sleep-aid solutions like blackout drapery, light boxes that help with wakefulness on night and early-morning shifts, and CPAP machines to help employees who struggle with conditions like sleep apnea.

Solutions for Safety and Success

Fatigue risk management is one of the most overlooked aspects of workplace safety — and yet, it’s also one of the most critical for workforce managers, especially in the manufacturing industry. But implementing effective strategies for mitigating (and preventing) workplace fatigue requires a much closer look at all aspects of your organization — all the way down to how much sleep your employees are realistically getting.